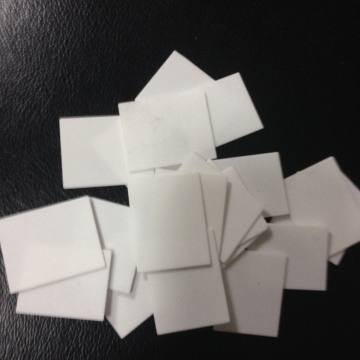

AlN ceramic substrate has high thermal conductivity, good electrical performance and non-toxic. It’s thermal expansion coefficient close to Si wafer, and it is an ideal material to replace BeO ceramics. It is mainly used in high-density hybrid circuits, microwave power devices, power electronic devices, optoelectronic components, semiconductor refrigeration and other products as high-performance substrate materials and packaging materials.。

| Item No. | Density(g/cm3) | Thermal Conductivity(W/m.K) | Thermal Expansion(x10-6/℃ | Dielectric Strength(Kv/mm) | Dielectric Constant(at 1MHz) | Loss Tangent(x104@1 MHz) | Volume Resistivity(ohm—cm) | Flexural Strength(Kg/mm2) |

| SD5111 | >3.20 | 80~100 | <4.5 | >15 | 9.0 | 3~10 | >1013 | >20 |

| SD5113 | >3.25 | 100~130 | <4.3 | >15 | 8.7 | 3~7 | >1014 | >25 |

| SD5115 | >3.25 | 140~170 | <4.3 | >15 | 8.7 | 3~7 | >1014 | >28 |

| SD5116 | 3.26 | >170 | <4.2 | >15 | 8.7 | 3~7 | >1014 | >30 |